Aluminum Pigment Selection for Architectural Powder Coating Systems

2025 / 12 / 16

Architectural powder coatings are no longer defined only by color.

Metallic appearance, long-term durability, and environmental stability have become core technical requirements for modern buildings.

Among metallic pigments, aluminum pigment for architectural powder coating plays a decisive role in both performance and aesthetics. Understanding its behavior, structure, and application logic is essential for architects, coating formulators, and façade engineers worldwide.

Aluminum Pigment for Architectural Powder Coating: Technical Fundamentals

Aluminum pigment for architectural powder coating consists of thin metallic flakes produced through controlled milling and classification processes.

Key technical parameters include:

-

Flake morphology and aspect ratio

-

Particle size distribution

-

Surface treatment chemistry

Controlled particle size aluminum pigment improves electrostatic deposition efficiency and promotes uniform flake orientation during curing. According to studies published in European Coatings Journal, optimized particle distribution can reduce metallic clouding by up to 25% on large architectural panels.

Weather Resistance and Exterior Performance Mechanisms

Exterior architectural coatings are continuously exposed to UV radiation, moisture, and temperature cycling.

The long-term stability of aluminum pigment depends on:

-

Oxide layer integrity

-

Surface passivation efficiency

-

Compatibility with powder resin systems

Non-leafing aluminum pigment for powder coating is commonly preferred for exterior architecture due to its stronger anchoring within the coating matrix, resulting in improved adhesion and corrosion resistance.

Research data from PCI Magazine indicates that non-leafing systems demonstrate superior metallic retention after 1,000+ hours of accelerated weathering compared to conventional leafing structures.

Leafing vs. Non-Leafing Aluminum Pigments in Architecture

The choice between leafing and non-leafing aluminum pigment for architectural coatings directly affects appearance and durability.

Leafing Aluminum Pigment for Architectural Coatings

-

Strong surface orientation

-

Higher initial brightness

-

Suitable for decorative or accent areas

Non-Leafing Aluminum Pigment for Powder Coating

-

Even flake distribution

-

Better mechanical strength

-

Preferred for large exterior surfaces

Selecting the correct structure depends on architectural design intent, exposure conditions, and maintenance expectations.

Application-Specific Considerations in Architectural Systems

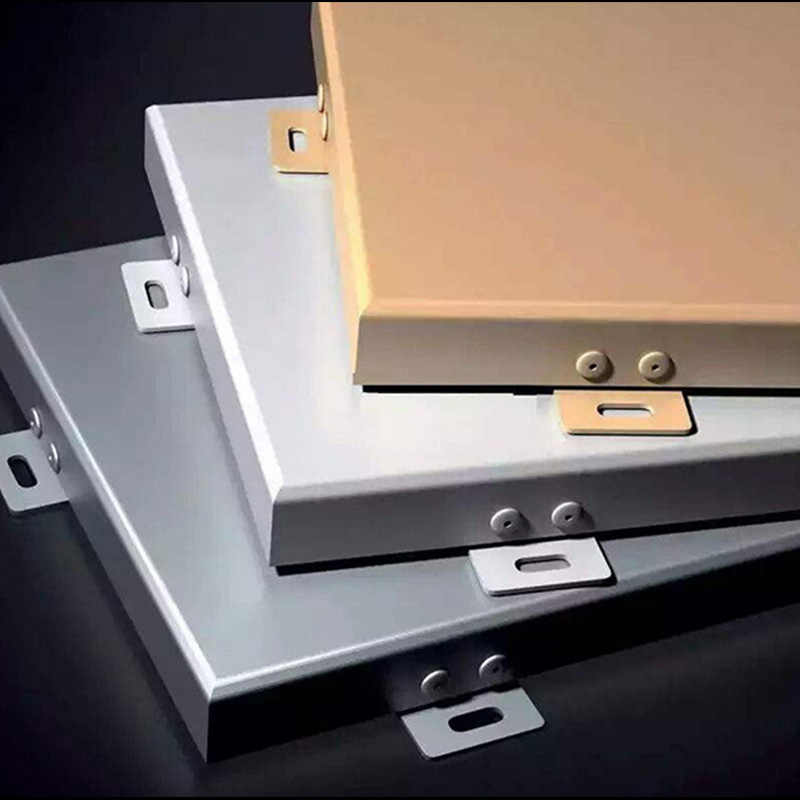

Curtain Wall Coatings

Large façades demand uniform metallic appearance and minimal visual variation. Controlled particle size aluminum pigment supports consistent orientation across wide panels.

Windows and Doors

Frequent handling and edge exposure require balanced metallic aesthetics and coating integrity. Non-leafing aluminum pigment enhances adhesion and wear resistance.

Aluminum Profiles and Extrusions

Complex geometries benefit from pigments with high dispersion stability, reducing edge thinning and uneven metallic buildup.

Performance Comparison in Architectural Powder Coatings

| Technical Factor | Leafing Aluminum Pigment | Non-Leafing Aluminum Pigment |

| Metallic Brightness | High | Moderate to high |

| Weather Resistance | Moderate | High |

| Adhesion | Limited | Strong |

| Exterior Suitability | Selective | Recommended |

Frequently Asked Questions

Why is particle size control critical in architectural powder coating?

Controlled particle size aluminum pigment ensures uniform electrostatic behavior and minimizes visual defects on large architectural surfaces.

Can aluminum pigment affect coating durability?

Yes. Improper pigment selection can accelerate oxidation or reduce adhesion, impacting long-term exterior performance.

Are aluminum pigments compatible with sustainable building standards?

Modern aluminum pigment systems are increasingly designed to support low-VOC powder coatings and sustainable architectural practices.

Conclusion

As architectural design continues to evolve toward larger surfaces, metallic aesthetics, and extended service life, the technical understanding of aluminum pigment for architectural powder coating becomes increasingly important.

Selecting the appropriate pigment structure, particle size, and performance profile is not a cosmetic decision, but a critical engineering choice that directly influences durability, appearance, and lifecycle performance in modern architecture.

- Previous:Aluminum Pigment for Powder Coating: Advanced Industrial Solutions

- Next:I have no